In this review, we present the latest highlights and trends in the use of core-shell particles as stationary phases in columns for liquid chromatography (LC). We review applications for developing and optimizing methods in liquid chromatography.We overview the theory of columns packed with core-shell particles from a practical viewpoint.We review fundamentals and applications of columns packed with core-shell particles.We review the analytical advantages of columns packed with core-shell particles.Core-shell particles are one of the hottest topics in analytical chemistry.

Core shell technology hplc full#

Unlock and download the full article for more.

Core shell technology hplc upgrade#

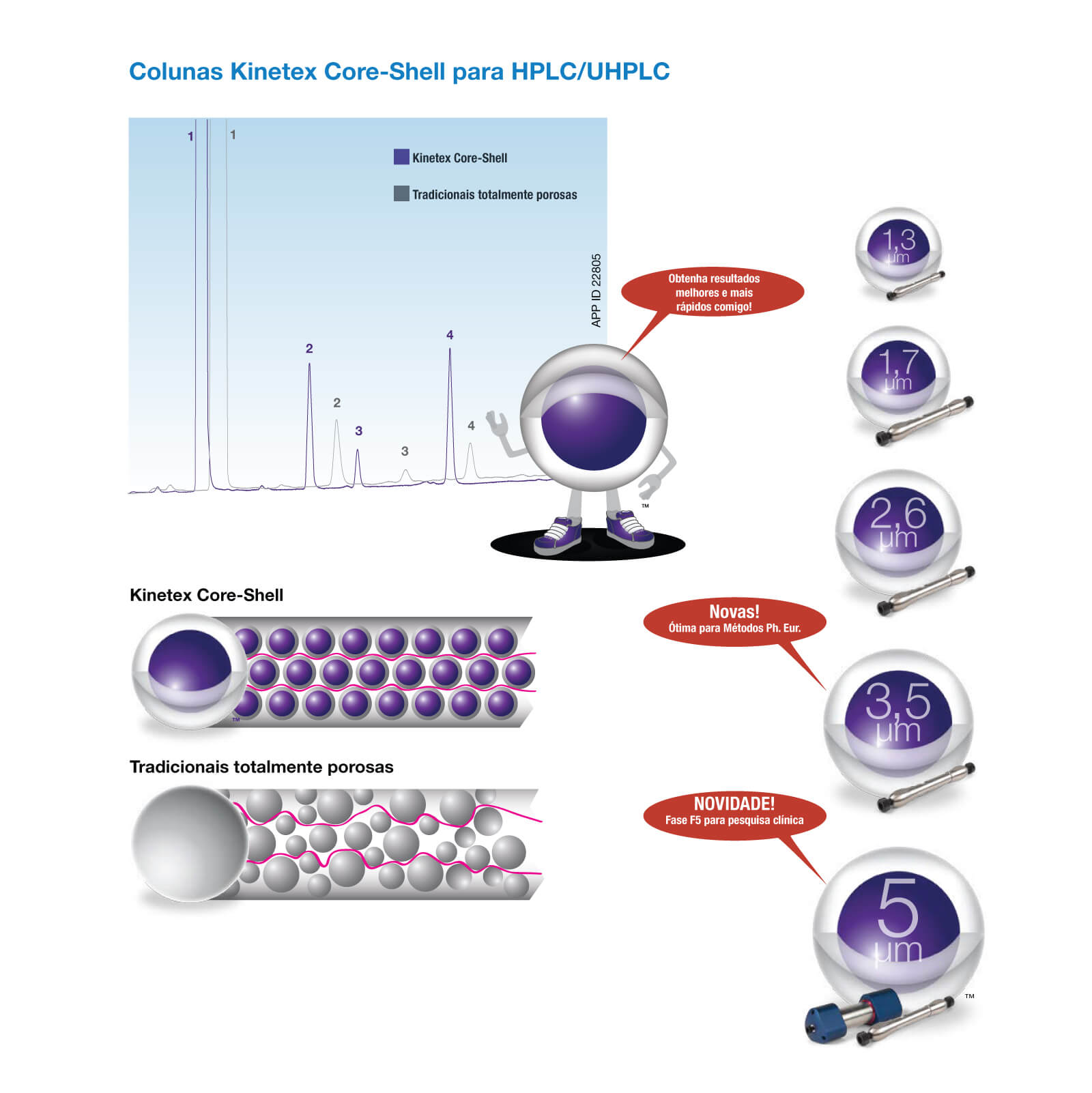

Meanwhile, HPLC chromatographers could upgrade their existing methods with ~2.6 μm core-shell columns that gave them a chance to see UHPLC results on HPLC systems, negating the need for expensive capital purchases of new instrumentation. With the sub-2 μm like efficiency at low backpressures, UHPLC scientists were given the ability to run faster and faster methods, while maintaining desired resolution and peak capacities. Thus, the sub-3 μm core-shell particles had the versatility to be compatible with both HPLC and UHPLC systems and, because of this flexibility this particle size range became the most widely applicable for most analytical labs. In fact, as has been demonstrated in numerous publications, columns packed with 2.6 μm core-shell particles were able to generate efficiency values that were equivalent to columns packed with 1.7 μm fully porous particles.

Columns packed with these particles were able to provide column efficiency values that were significantly greater than those of conventional fully porous 3 μm particles, but operated at comparable pressures. Initially, core-shell particles were only available in sub-3 μm (typically 2.6 or 2.7 μm) formats. The increased availability of core-shell media has resulted in a boon for chromatographers, as core-shell products now exist in an incredible amount of formats and selectivities to fit virtually any separation situation. However, over time manufacturing improvements and technological advancements made core-shell particle development technology accessible to a broader range of media manufacturers, and now the number of core-shell suppliers has significantly increased (alongside an even larger increase in the number of core-shell distributors).

In order to gain a clear perspective into what the future might hold for core-shell particles, it is first important to quickly recap the evolution of core-shell technology in recent years.ĭue to the technological hurdles of manufacturing core-shell particles, there were just three core-shell manufacturers in 2009. Most importantly, though, the recent development of new surface chemistries combined with innovations in core-shell media manufacturing have enabled core-shell products to keep pace with the market’s separation needs and to overcome increasingly demanding challenges and obstacles. Even conservative pharmacopeia and compendial methods have begun accepting and labelling method updates with core-shell products. As of today, analysts, in virtually any industry that performs liquid chromatography can depend on core-shell columns because of their proven superior performance and wide reaching benefits compared to traditional and conventional HPLC, UHPLC and Preparative HPLC products. Based upon our experience with both fully porous and core-shell based liquid chromatography products, we believe that, in the coming years, core-shell technology will continue to provide increasing benefits to separation scientists including greater sample throughput, improved sensitivity, and increased resolution as well as more compatibility across various instrumentation platforms. Since their introduction in the late-2000s, core-shell particles (alternatively referred to as superficially porous particles), have become increasingly used across the HPLC/UHPLC landscape.

0 kommentar(er)

0 kommentar(er)